The Optical Properties of Plastic Lenses

Plastic materials and injection molding are the basis for miniaturized lenses. The structure of the plastic lens includes lens material, lens barrel, lens mount, spacer, shading sheet, pressure ring material, etc.

There are several types of lens materials for plastic lenses, all of which are essentially plastic (high molecular polymer). They are thermoplastics, plastics that soften and become plastic when heated, harden when cooled, and soften when heated again. A physical change that produces a reversible change between liquid and solid states using heating and cooling. Some materials were invented earlier and some are relatively new. Some are general-purpose application plastics, and some materials are specially developed optical plastic materials, which are more specifically used in some optical fields.

In optical design, we may see the material grades of various companies, such as EP8000, K26R, APL5015, OKP-1 and so on. They all belong to a certain type of plastic material, and the following types are more common, and we will sort them according to their appearance time:

The plastic lenses

- l PMMA/Acrylic: Poly(methyl methacrylate), polymethyl methacrylate (plexiglass, acrylic). Due to its cheap price, high transmittance, and high mechanical strength, PMMA is the most common glass substitute in life. Most of the transparent plastics are made of PMMA, such as transparent plates, transparent spoons, and small LEDs. lens etc. PMMA has been mass-produced since the 1930s.

- PS: Polystyrene, polystyrene, is a colorless and transparent thermoplastic, as well as an engineering plastic, which began mass production in the 1930s. Many of the white foam boxes and lunch boxes that are common in our lives are made of PS materials.

- PC: Polycarbonate, polycarbonate, is also a colorless and transparent amorphous thermoplastic, and it is also a general-purpose plastic. It was only industrialized in the 1960s. The impact resistance of PC material is very good, common applications include water dispenser buckets, goggles, etc.

- l COP & COC: Cyclic olefin Polymer (COP), Cyclic olefin polymer; Cyclic olefin copolymer (COC) Cyclic olefin copolymer, is an amorphous transparent polymer material with a ring structure, with carbon-carbon double bonds in the ring The cyclic hydrocarbons are made from cyclic olefin monomers by self-polymerization (COP) or copolymerization (COC) with other molecules (such as ethylene). The characteristics of COP and COC are almost the same. This material is relatively new. When it was first invented, it was mainly considered for some optical related applications. Now it is widely used in film, optical lens, display, medical (packaging bottle) industries. COP completed industrial production around 1990, and COC completed industrial production before 2000.

- l O-PET: Optical polyester optical polyester fiber, O-PET was commercialized in Osaka in the 2010s.

When analyzing an optical material, we are mainly concerned with their optical and mechanical properties.

Optical properties

-

Refractive Index & Dispersion

Refractive index and dispersion

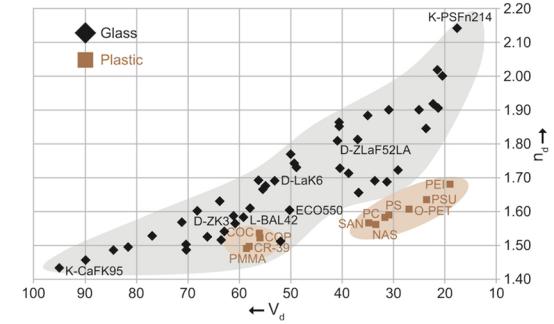

It can be seen from this summary diagram that different optical plastic materials basically fall into two intervals: one group is high refractive index and high dispersion; the other group is low refractive index and low dispersion. Comparing the optional range of refractive index and dispersion of glass materials, we will find that the optional range of refractive index of plastic materials is very narrow, and all optical plastic materials have a relatively low refractive index. Generally speaking, the range of options for plastic materials is narrower, and there are only about 10 to 20 commercial material grades, which largely limits the freedom of optical design in terms of materials.

Refractive index varies with wavelength: The refractive index of optical plastic materials increases with wavelength, the refractive index decreases slightly, and the overall is relatively stable.

Refractive index changes with temperature Dn/DT: The temperature coefficient of refractive index of optical plastics is 6 times to 50 times larger than that of glass, which is a negative value, which means that as the temperature increases, the refractive index decreases. For example, for a wavelength of 546nm, -20°C to 40°C, the dn/dT value of the plastic material is -8 to -15X10^–5/°C, while in contrast, the value of the glass material NBK7 is 3X10^–6/°C.

-

Transmittance

The transmittance

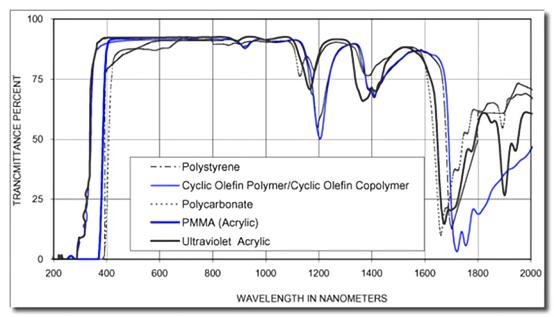

Referring to this picture, most optical plastics have a transmittance of more than 90% in the visible light band; they also have a good transmittance for the infrared bands of 850nm and 940nm, which are common in consumer electronics. The transmittance of plastic materials will also decrease to a certain extent with time. The main reason is that the plastic absorbs the ultraviolet rays in the sun, and the molecular chain breaks to degrade and cross-link, resulting in changes in physical and chemical properties. The most obvious macroscopic manifestation is the yellowing of the plastic material.

-

Stress Birefringence

Lens Refraction

Stress birefringence (Birefringence) is an optical property of materials. The refractive index of materials is related to the polarization state and propagation direction of incident light. Materials exhibit different indices of refraction for different polarization states. For some systems, this refractive index deviation is very small and does not have a great impact on the system, but for some special optical systems, this deviation is enough to cause serious degradation of system performance.

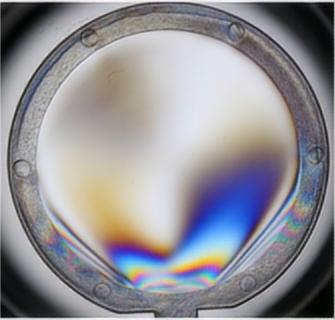

Plastic materials themselves do not have anisotropic characteristics, but injection molding of plastics will introduce stress birefringence. The main reason is the stress introduced during injection molding and the arrangement of plastic macromolecules after cooling. The stress is generally concentrated near the injection port, as shown in the figure below.

The general design and production principle is to minimize the stress birefringence in the optical effective plane, which requires a reasonable design of the lens structure, injection molding mold and production parameters. Among several materials, PC materials are more prone to stress birefringence (about 10 times larger than PMMA materials), and COP, COC, and PMMA materials have lower stress birefringence.