Application Advantages Of Machine Vision Lenses In Aperture Detection

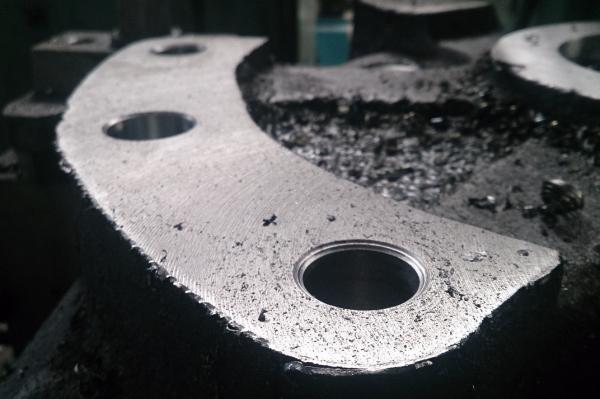

The application of machine vision lenses in the field of inner hole inspection has significant advantages, bringing unprecedented convenience and efficiency improvements to many industries.

Comprehensive testing

Traditional internal hole inspection methods usually require the workpiece to be rotated multiple times or use multiple tools to complete a comprehensive inspection.

Using machine vision lenses, especially 360° internal hole inspection lenses, the entire internal hole can be inspected at one angle without frequently adjusting the position of the workpiece, greatly improving inspection efficiency and accuracy.

High-resolution imaging

Machine vision lenses are made of high-quality optical materials and precision manufacturing processes to provide clear, high-resolution imaging quality. This can clearly display various defects, foreign objects and details in the hole, which helps to find and solve problems in time and ensure the quality of the product.

Highly adaptable

Machine vision lenses can be used with various types of inspection equipment to adapt to different inspection scenarios. Whether it is aerospace, power generation, automotive manufacturing or any other industry, you can find an machine vision lens that suits your aperture inspection needs.

Machine vision lenses can adapt to different detection scenarios

Flexibility and accessibility

Machine vision lenses are usually small and light, easy to carry and simple to operate, so they can be used in a variety of environments, whether it is a small space or a complex field environment.

Advanced image control features

Some advanced machine vision lenses are also equipped with clear imaging technology based on CCD image sensors and various advanced image control functions, such as dark enhancement, adaptive noise reduction ANR, distortion correction and color saturation adjustment.

These functions make the inspection image clearer and more accurate, helping to discover more details and potential problems.

Intelligent assistance function

Some machine vision lenses also have intelligent auxiliary functions, such as ADR artificial intelligence assisted defect judgment function, blade intelligent counting and analysis function, etc.

These functions can automatically identify and record defects, analyze the number of blade grades, etc., reduce the repetitive work of drilling inspection personnel, and improve inspection efficiency and accuracy.

Machine vision lenses help improve inspection efficiency

Measurement functions

The measurement capability of industrial endoscopes is particularly important in aerospace drilling exploration. Machine vision lenses combined with imaging systems and image processing algorithms can achieve high-precision measurement of aperture size, shape and position.

By using machine vision lenses, the size and location of defects can be accurately measured, providing the necessary data support to evaluate the impact of defects on the engine.

Diverse Applications

Machine vision lenses are also suitable for aperture detection of different shapes and sizes, and are widely used in many fields including metal processing, electronic components, optical elements, etc.

Final Thoughts:

ChuangAn has carried out the preliminary design and production of machine vision lenses, which are used in all aspects of machine vision systems. If you are interested in or have needs for machine vision lenses, please contact us as soon as possible.