How To Confirm The Resolution Of Industrial Lenses? What Are Its Functions?

1、How to confirm the resolution of industrial lenses?

To confirm the resolution of an industrial lens, some measurements and tests are usually required. Let’s take a look at several common methods to confirm the resolution of industrial lenses:

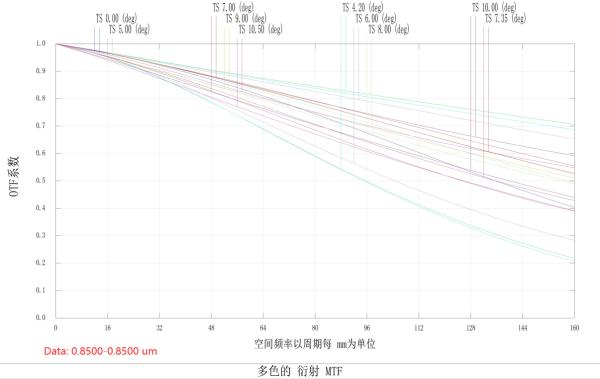

MTF Measurement

The resolution capability of a lens can be evaluated by testing the Modulation Transfer Function (MTF) of the lens. MTF measurement can reveal the lens’s ability to transmit details at different frequencies and contrasts, thereby judging the lens’s resolution performance.

Resolution test image

Use a resolution test image with high contrast and detail to evaluate the resolution capability of the lens. By observing the details and edge conditions in the image, you can initially judge the resolution performance of the lens.

Use images to test resolution

Use resolution test charts

In practical applications, lens resolution can be tested using resolution test charts designed specifically for testing lens resolution. These charts contain a series of small lines or patterns that allow you to evaluate the resolution of a lens by observing how sharp and discernible these patterns are in the image.

Use professional equipment

If a more accurate resolution measurement is required, professional optical equipment and software can be used to perform more detailed resolution tests.

Observe image quality

You can use this industrial lens to shoot an object and observe the clarity and detail of the image. If the image is clear, detailed, and has high color accuracy and contrast, it means that the lens may have a high resolution.

Reference manufacturer specifications

Lens manufacturers usually provide information about lens resolution in the product specification, including data such as maximum resolution value or MTF curve. You can also refer to the specification provided by the manufacturer to understand the resolution performance of the lens.

Refer to data provided by the manufacturer

2、What are the main functions of industrial lenses?

As a specialized optical lens for industrial vision applications, the main functions of industrial lenses include the following:

Detection and Identification

Industrial lenses, when combined with cameras and light sources, can be used to detect surface defects, measure dimensions, identify text or patterns, and achieve automatic quality control and production process monitoring. This improves production efficiency and product quality.

Functions of industrial lenses

Image Acquisition

Industrial lenses can capture high-resolution, low-distortion, high-contrast images, ensuring the clarity and accuracy of the captured images, providing a reliable foundation for subsequent image processing and analysis.

Data Acquisition

Image data acquired through industrial lenses can be used for statistical analysis, data recording, and fault diagnosis, helping enterprises optimize and improve their production processes.

Visual Guidance

Industrial lenses can be used for tasks such as positioning, navigation, and recognition in machine vision systems, providing visual guidance for robots and automated equipment, and achieving automated production and operation.

Final Thoughts:

ChuangAn has carried out the preliminary design and production of industrial lenses, which are used in all aspects of industrial applications. If you are interested in or have needs for industrial lenses, please contact us as soon as possible.