What is a Time of Flight (ToF) Sensor?

1. What is a time-of-flight (ToF) sensor?

What is a time-of-flight camera? Is it the camera that captures the flight of the plane? Does it have something to do with planes or planes? Well, it’s actually a long way off!

ToF is a measure of the time it takes for an object, particle or wave to travel a distance. Did you know that a bat’s sonar system works? The time-of-flight system is similar!

There are many kinds of time-of-flight sensors, but most are time-of-flight cameras and laser scanners, which use a technology called lidar (light detection and ranging) to measure the depth of various points in an image by shining it with infrared light.

Data generated and captured using ToF sensors is very useful as it can provide pedestrian detection, user authentication based on facial features, environment mapping using SLAM (simultaneous localization and mapping) algorithms, and more.

This system is actually widely used in robots, self-driving cars, and even now your mobile device. For example, if you are using Huawei P30 Pro, Oppo RX17 Pro, LG G8 ThinQ, etc., your phone has a ToF camera!

A ToF camera

2. How does the time-of-flight sensor work?

Now, we‘d like to give a brief introduction of what a time-of-flight sensor is and how it work.

ToF sensors use tiny lasers to emit infrared light, where the resulting light bounces off any object and returns to the sensor. Based on the time difference between the emission of light and the return to the sensor after being reflected by the object, the sensor can measure the distance between the object and the sensor.

Today, we will explore 2 ways how ToF uses travel time to determine distance and depth : using timing pulses, and using phase shifting of amplitude modulated waves.

Use timed pulses

For example, it works by illuminating a target with a laser, then measuring the reflected light with a scanner, and then using the speed of light to extrapolate the distance of the object to precisely calculate the distance traveled. In addition, the difference in laser return time and wavelength is then used to make an accurate digital 3D representation and surface features of the target, and visually map out its individual features.

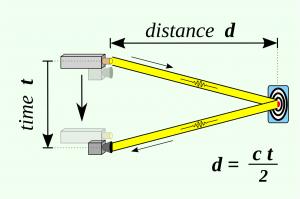

As you can see above, laser light is fired out and then bounce off the object back to the sensor. With the laser return time, ToF cameras are able to measure accurate distances in a short period of time given the speed of light travel. (ToF converts to distance) This is the formula an analyst uses to arrive at the exact distance of an object:

(speed of light x time of flight) / 2

ToF converts to distance

As you can see, the timer will start while the light is off, and when the receiver receives the return light, the timer will return the time. When subtracting twice, the “time of flight” of light is obtained, and the speed of light is constant, so distance can be easily calculated using the formula above. In this way, all points on the surface of the object can be determined.

Use the phase shift of the AM wave

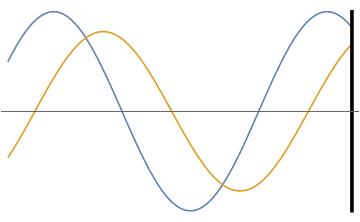

Next, the ToF can also use continuous waves to detect the phase shift of the reflected light to determine depth and distance.

Phase shift using AM wave

By modulating the amplitude, it creates a sinusoidal light source with a known frequency, allowing the detector to determine the phase shift of the reflected light using the following formula:

where c is the speed of light (c = 3 × 10^8 m/s), λ is a wavelength (λ = 15 m), and f is the frequency, each point on the sensor can be easily calculated in depth.

All of these things happen very fast as we work at the speed of light. Can you imagine the precision and speed with which sensors are able to measure? Let me give an example, light travels at a speed of 300,000 kilometers per second, if an object is 5m away from you, the time difference between the light leaving the camera and returning is about 33 nanoseconds, which is only equivalent to 0.000000033 seconds! Wow! Not to mention, the captured data will give you an accurate 3D digital representation for every pixel in the image.

Regardless of the principle used, providing a light source that illuminates the entire scene allows the sensor to determine the depth of all points. Such a result gives you a distance map where each pixel encodes the distance to the corresponding point in the scene. The following is an example of a ToF range graph:

An example of a ToF range graph

Now that we know that ToF works, why is it good? Why use it? What are they good for? Don’t worry, there are many advantages to using a ToF sensor, but of course there are some limitations.

3. The benefits of using time-of-flight sensors

Accurate and fast measurement

Compared to other distance sensors such as ultrasound or lasers, time-of-flight sensors are able to compose a 3D image of a scene very quickly. For example, a ToF camera can do this only once. Not only that, the ToF sensor is able to detect objects accurately in a short time and is not affected by humidity, air pressure and temperature, making it suitable for both indoor and outdoor use.

long distance

Since ToF sensors use lasers, they are also capable of measuring long distances and ranges with high accuracy. ToF sensors are flexible because they are able to detect near and far objects of all shapes and sizes.

It is also flexible in the sense that you are able to customize the optics of the system for optimal performance, where you can choose the transmitter and receiver types and lenses to get the desired field of view.

Safety

Worried that the laser from the ToF sensor will hurt your eyes? don’t worry! Many ToF sensors now use a low-power infrared laser as the light source and drive it with modulated pulses. The sensor meets Class 1 laser safety standards to ensure it is safe to the human eye.

cost effective

Compared to other 3D depth range scanning technologies such as structured light camera systems or laser rangefinders, ToF sensors are much cheaper compared to them.

Despite all these limitations, ToF is still very reliable and a very fast method of capturing 3D information.

4. Limitations of ToF

Although ToF has many benefits, it also has limitations. Some of the limitations of ToF include:

-

Scattered light

If very bright surfaces are very close to your ToF sensor, they may scatter too much light into your receiver and create artifacts and unwanted reflections, since your ToF sensor only needs to reflect the light once measurement is ready.

-

Multiple reflections

When using ToF sensors on corners and concave shapes, they can cause unwanted reflections, as the light can bounce off multiple times, distorting the measurement.

-

Ambient light

Using the ToF camera outdoors in bright sunlight can make outdoor use difficult. This is due to the high intensity of sunlight causing the sensor pixels to quickly saturate, making it impossible to detect the actual light reflected from the object.

-

The conclusion

ToF sensors and ToF lens can be used in a variety of applications. From 3D Mapping, Industrial Automation, Obstacle Detection, Self-Driving Cars, Agriculture, Robotics, Indoor Navigation, Gesture Recognition, Object Scanning, Measurements, Surveillance to Augmented Reality! The applications of ToF technology are endless.

You can contact us for any needs of ToF lenses.

Chuang An Optoelectronics focuses on high-definition optical lenses to create a perfect visual brand

Chuang An Optoelectronics has now produced a variety of TOF lenses such as:

CH3651A f3.6mm F1.2 1/2″ IR850nm

CH3651B f3.6mm F1.2 1/2″ IR940nm

CH3652A f3.3mm F1.1 1/3″ IR850nm

CH3652B f3.3mm F1.1 1/3″ IR940nm

CH3653A f3.9mm F1.1 1/3″ IR850nm

CH3653B f3.9mm F1.1 1/3″ IR940nm