What Needs To Be Understood In The Customization And Design Of Optical Lenses

Optical lenses are now widely used in various fields, including cameras, telescopes, microscopes, laser systems, fiber optic communications, etc. Through excellent design and manufacturing technology, optical lenses can meet the optical needs in different application scenarios, providing clear and accurate image capture and optical transmission functions.

An optical lens needs to go through different steps such as design, processing, and testing before leaving the factory. Design is the first step, and it is very important to grasp the needs of the lens.

Design of optical lenses

Understanding the needs can help optical lens customization and designers accurately grasp customer needs and provide solutions that are more in line with actual application needs.

So, what needs to be understood for the customization and design of optical lenses?

Application scenario needs

First of all, you need to clearly tell the technicians what the specific application field is for using the optical lens and what the functional requirements are. Different application scenarios may have different requirements for the parameters, optical performance and materials of optical lenses.

For example, different application fields such as computer vision, industrial measurement, and medical imaging have different requirements for lenses.

Optical performance requirements

Understand the requirements for optical parameters, including focal length, field of view, distortion, resolution, focus range, etc. These parameters are directly related to the performance of the optical system. Based on application requirements, determine whether special optical designs are required, such as aspherical lenses, vignetting filters, etc.

In addition, the spectral range of the lens application also needs to be considered. Because the lens design must consider chromatic aberration, material and other characteristics, it is necessary to know the spectral range of the lens when it is used.

If you are using monochromatic light, such as red light, green light, blue light, etc., or using full spectrum white light, or using near infrared, short-wave infrared, medium-wave infrared, long-wave infrared, etc.

An optical lens

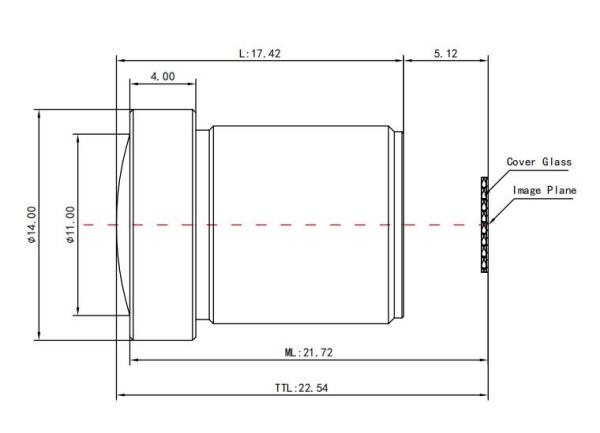

Mechanical parameter requirements

In addition to optical performance requirements, designing a lens also requires understanding mechanical requirements, such as lens size, weight, mechanical stability, etc. These parameters influence the mounting and integration of optical lenses.

Specific environmental requirements

Optical lenses will operate in a specific environment, and the impact of environmental factors such as temperature, humidity, and pressure on the lens needs to be considered. If the working environment is harsh or there are special requirements, the optical lens needs to be protected or special materials selected.

Production volume and cost requirements

Designers will determine the production process and cost of the optical lens based on application needs and production volume requirements. It mainly includes selecting appropriate processing methods, materials and coating technologies, as well as cost evaluation and control.